Maps Galore: A 3D Printing Production Line

What does more 10,000 hours of 3D print time look like? Well that's how long it took us to print 250 maps of Fife in Scotland!

In late 2021, Katie Palmer from a premium single malt whisky distillery in Fife Scotland approached us to design and produce more than two hundred maps to be used in special boxes for their whisky release later in 2022. This project summarises the map design and production process and put the industrial in cottage industry!

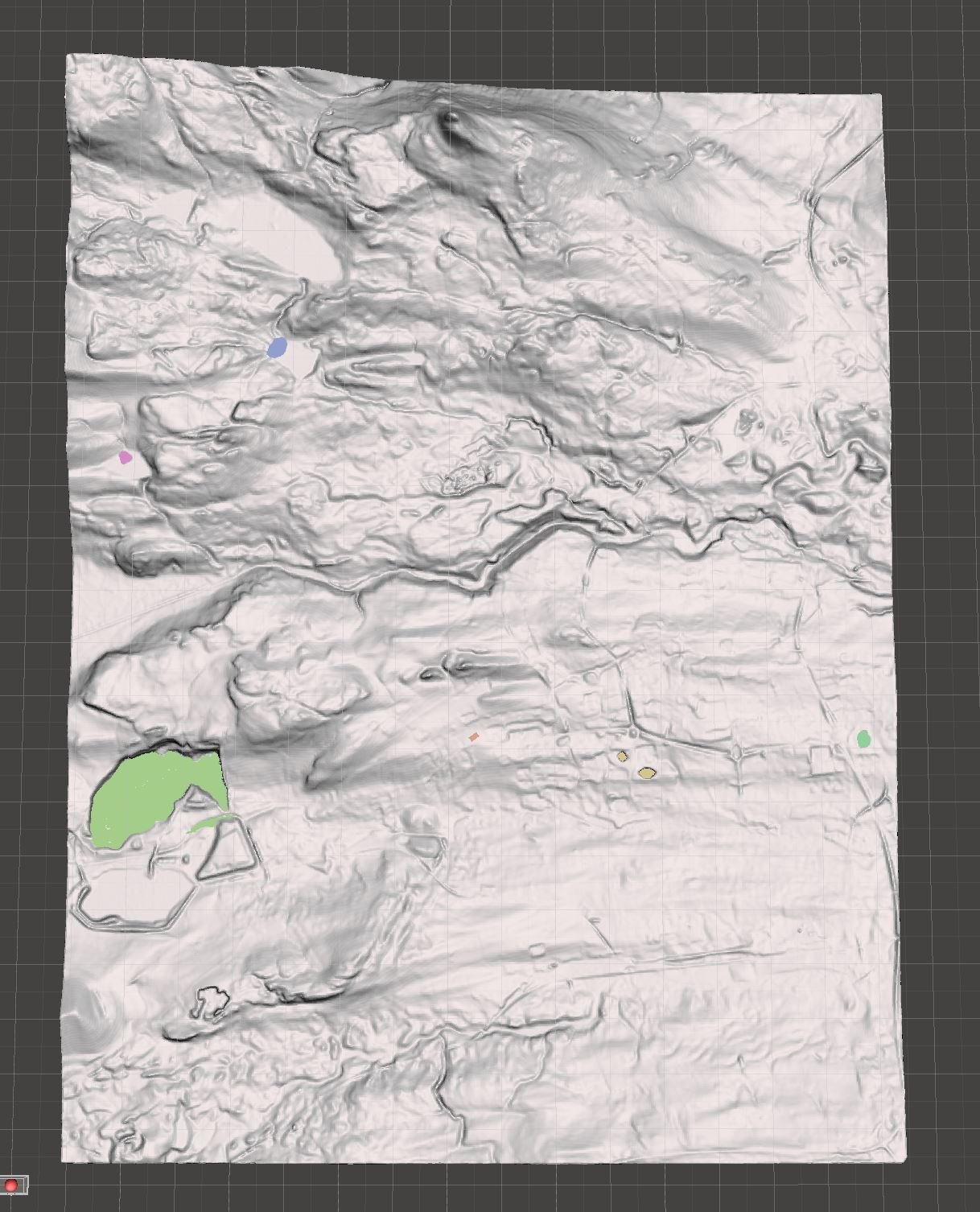

Firstly, we had to agree upon a design and a rough area of interest. They wanted the map to be centred on the distillery, but also include the Lomond Hills and parts of Loch Leven. Our initial renders included a larger area down to the coast at Kirkcaldy. The clients were also unsure of the size they wanted for the map, whether they wanted the piece printed at 10cm, 15cm or 20cm squared.

Some of the initial designs.

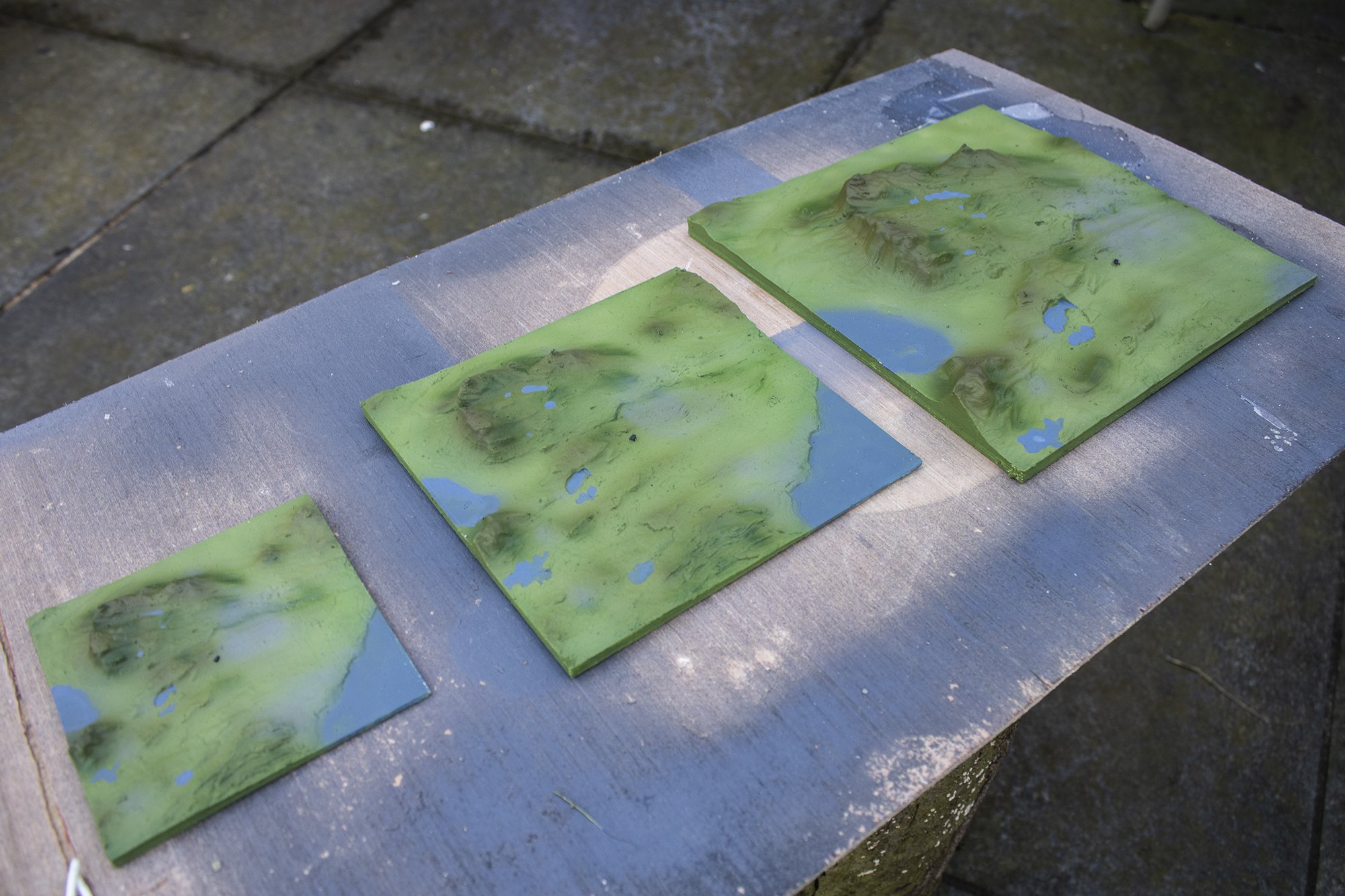

Together we quickly established a square, focused 20cm map was required.

We also produced a cast resin version from a silicone mould. But between the client needing a light model for the box and rather expensive resin costs we worked out the best way forward. To be precise, we decided early on that 15% infill for a 20cm squared map, printed to a 0.12 layer height in PLA on our FDM machines was the way forward.

Next the focus or framing of the maps was decided - that is, what area the map covers - in this case they wanted a smaller area focused around the distillery. Also discussed was what finish the client would want. Normally our maps are coloured by hand in a naturalistic style based on aerial and satellite photography. We offered a few versions which used the distillery's distinctive black, grey, and copper colouring present on their livery.

Ultimately, the client decided the standard naturalistic colour was most appropriate. Additionally, they wanted some annotation to the model in this case several simple pins placed at key locations relating to areas where their grain was sourced. Given so many were to be printed the design and finishing process was particularly important.

Print time on each map was around 36-48 hours depending on the model of printer used, this equated to 9000 to 12000 hours of machine time for the full set of 250 models. Given there were various prototypes, at least 15% print failure rate and a good will gesture of around 12 maps to ensure quality control and spares; we were looking at 16 months of machine time in total.

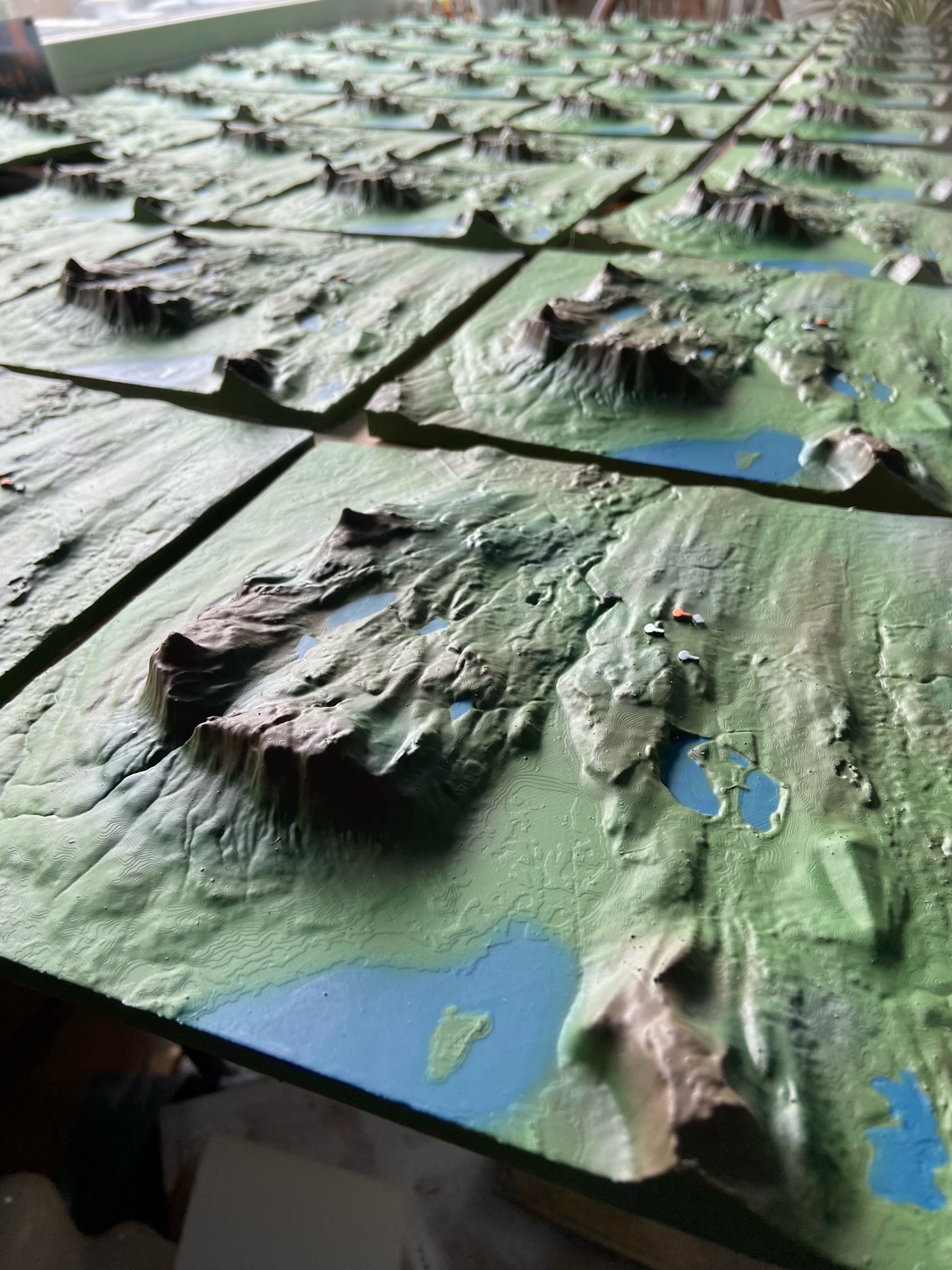

The batches, hot off the press!

Here is one batch of 50 and one of 100 - no room for heavy shoes!

We printed continuously from April to July. Painting in batches of 50 as the maps were ready. Each required finishing; sanding nubs and any stringing, as well as priming in an undercoat - about an hours work. We then used a benchmark model to make sure we had uniformity in the colour - each taking around 3 hours to paint.

Scheduling was met on most of the batches, importantly the last batch went out on time at around our higher margin dispatch date. In all we used around 35kg-40kg of PLA.

At the time this was the largest commission we'd taken on. And shows even a small printing house can have impressive production line prints - if you're willing to put the blood, sweat, and tears in!